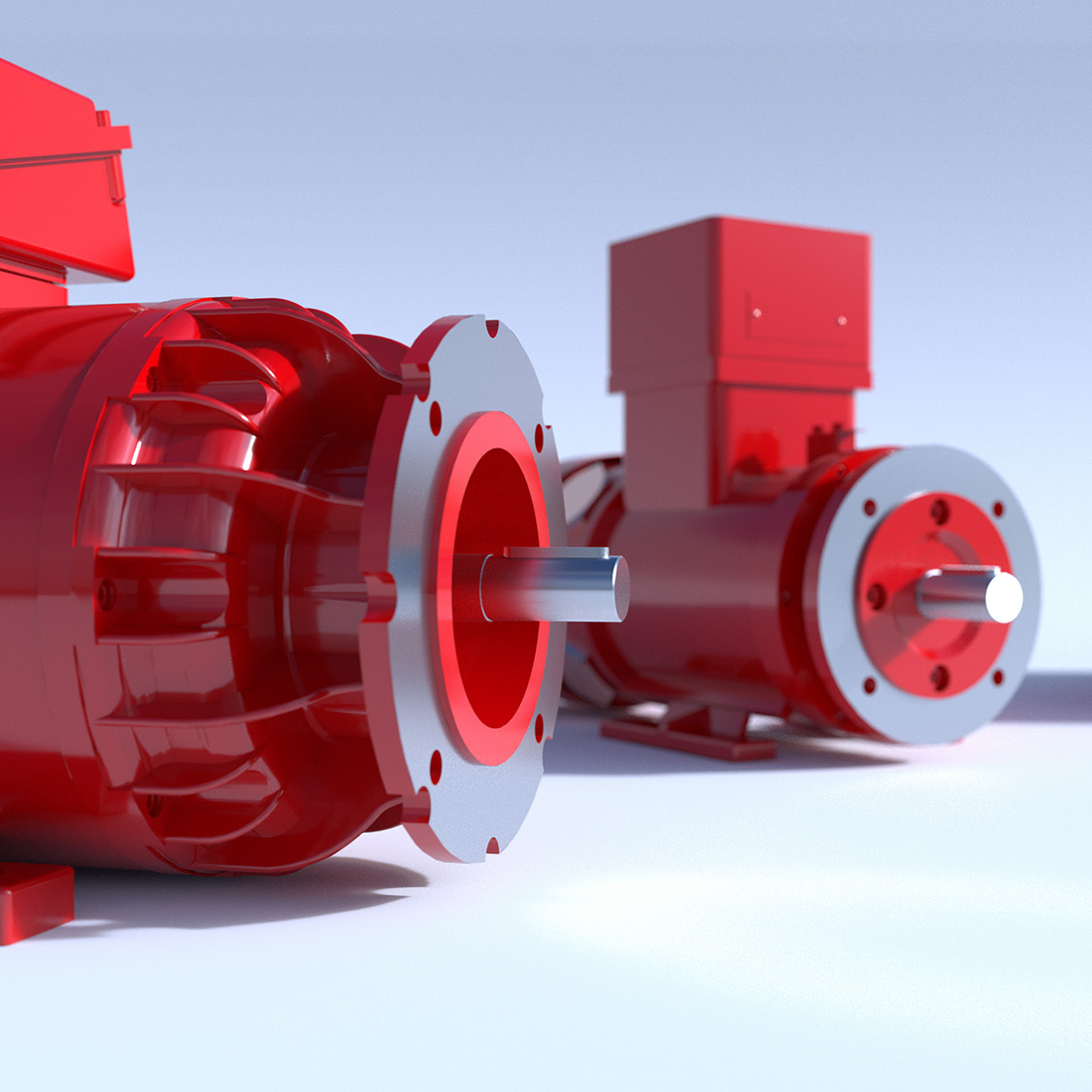

Tailor-Made Design, Development and Manufacturing of Electrical Motors

WINKELMANN Elektromotoren is your holistic system provider for the

development and manufacture of three-phase and DC motors.

Customised assembly and manufacture. In line with your requirements and incorporating our know-how.

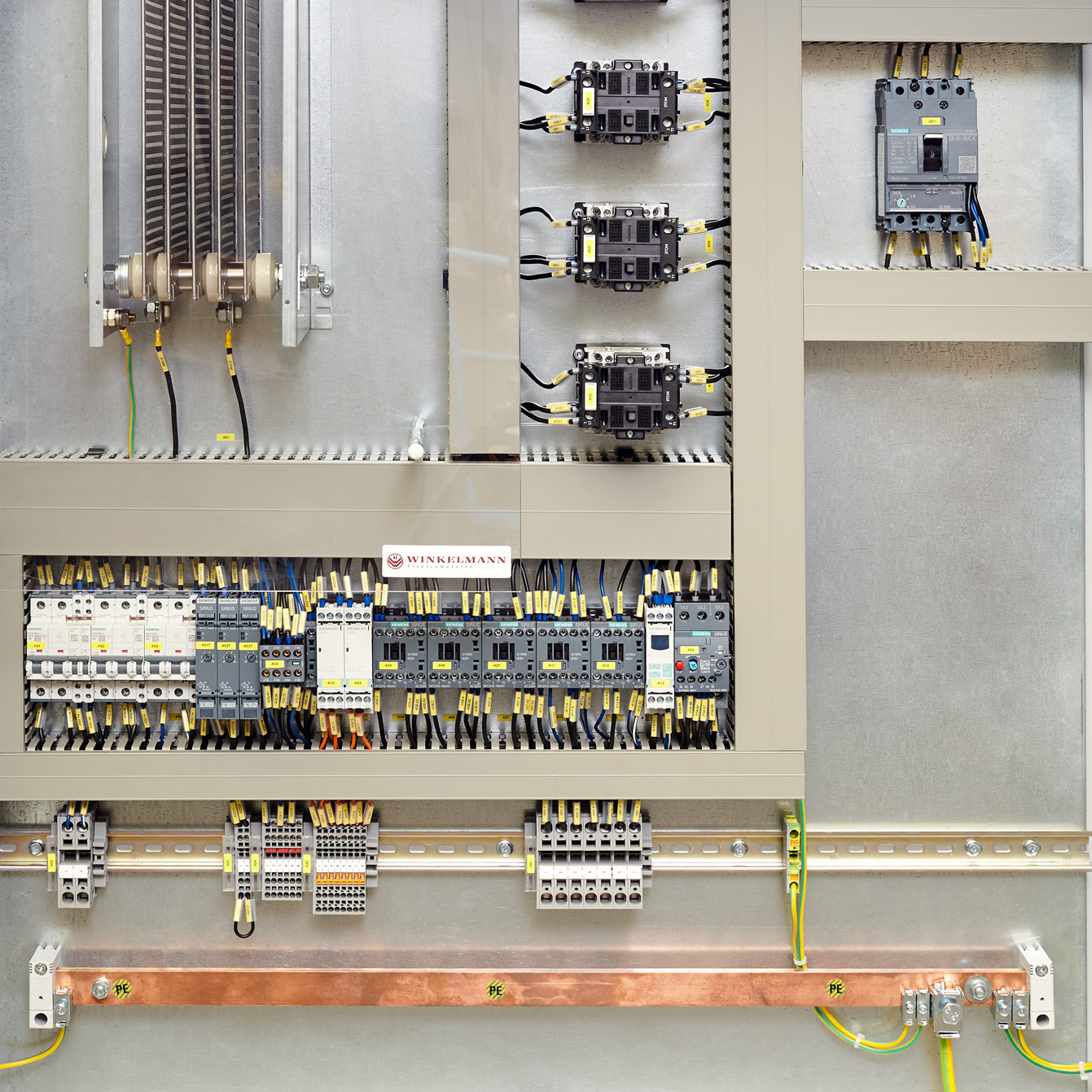

Our full-service portfolio for our electric motors ranges from planning, development and prototype construction, manufacturing, product testing and integration of system modules, through to installation, commissioning, service, repairs and maintenance.

Latest News

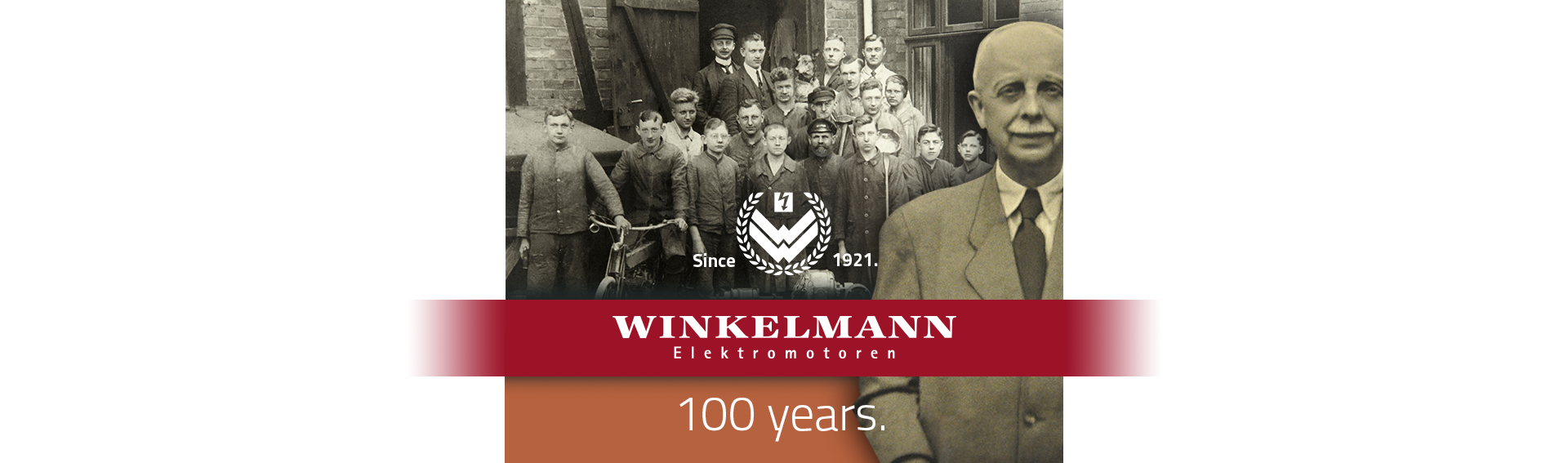

Thanks for 100 years of Winkelmann!

It started on October 1, 1921! Our company founder and visionary Wilhelm Winkelmann went off to start his company and built it up. Winkelmann [...]

Introducing new Electrical Motor Product Portfolio for Test Bench Application

After the completion of the innovation project, WINKELMANN is expanding its product range portfolio to include the new product lines for three-phase [...]

Welcome to our new website

www.w-winkelmann.de now appears in a new design and with a greatly expanded range of products and services. Our full-service portfolio for our [...]

Special coatings now on offer

WINKELMANN now offers coatings for corrosivity categories C2 to C5 in accordance with DIN EN ISO 12944. These range from special electrically [...]

Mit einem Klick hier gelangen Sie zu unseren aktuellen Stellenangeboten.